In today's dynamic global marketplace, businesses are constantly seeking methods to enhance efficiency, reduce costs, and gain a competitive edge. Joint ventures within supply chains have emerged as a powerful tool to achieve these objectives. These partnerships involve several parties that collaborate to leverage their respective strengths and resources, building a more robust and resilient supply chain network.

The benefits of strategic alliances in supply chains are manifold. Initially, they enable organizations to access new markets, technologies, and expertise. By sharing resources and knowledge, partners can grow their reach and capabilities. Additionally, these alliances can lead to reduced expenses through economies of scale, shared infrastructure, and streamlined processes.

- Additionally, strategic alliances can enhance risk management by diversifying supply sources and mitigating the impact of disruptions.

- By means of collaborative innovation, partners can develop new products and services that meet evolving customer demands.

Nevertheless, implementing successful strategic alliances demands careful planning, clear communication, and a strong commitment from all parties involved. Creating mutually beneficial goals, roles, and responsibilities is crucial for ensuring the long-term success of these partnerships.

Types of Supply Chain Partnerships for Enhanced Efficiency

Supply chain partnerships establish a fundamental role in driving efficiency within modern businesses. These collaborations encompass a varied range of frameworks, each with its own advantages and deployments. Collaborative partnerships often engage a deep degree of collaboration between companies, emphasizing on common objectives. These partnerships can generate significant benefits such as reduced costs, improved product quality, and accelerated time-to-market. In contrast, operational partnerships are more limited in scope, often concentrating on a particular business process. These partnerships can provide flexibility and allow businesses to leverage specialized expertise as needed. It is essential for businesses to meticulously analyze their specific needs when selecting the optimal type of supply chain partnership. By utilizing the right collaboration strategy, organizations can achieve significant enhancements and gain a market edge in today's dynamic marketplace.

Exploring Collaborative Supply Chain Models

Collaborative supply chain models are becoming increasingly popular as businesses seek to improve efficiency and agility. These models require a high degree of cooperation between different players in the supply chain, including suppliers, distributors, retailers, and even customers. To successfully navigate these collaborative arrangements, it's crucial to establish clear channels of communication, foster strong relationships, and implement robust technology that facilitate information dissemination. A well-structured collaborative supply chain can yield a number of gains, such as minimized costs, improved lead times, and heightened customer loyalty. However, there are also some challenges associated with collaborative supply chain models. These can include differences in business practices, tension over data sharing, and the demand for a high level of confidence between partners. Tackling these challenges requires careful consideration, transparent communication, and a willingness to partner.

Collaborative Partnerships: A Powerful Tool for Supply Chain Collaboration

In today's volatile global marketplace, supply chains are constantly adapting. To remain competitive, businesses must enhance their operations and foster robust collaboration throughout the supply chain. One powerful tool that facilitates this is the joint venture.

A joint venture involves two or more companies pooling their resources, expertise, and technologies to achieve a common objective. By combining their strengths, businesses can reduce risks, unlock new markets, and enhance innovation.

- Merits of joint ventures in supply chain collaboration include:

- Optimized efficiency through shared resources and expertise.

- Minimized costs by collaborating procurement and logistics operations.

- Heightened competitiveness through access to new markets and technologies.

- Strengthened risk management through shared responsibilities and liabilities.

Effects of Outsourcing on Supply Chain Collaboration

Outsourcing drastically alters the dynamics within supply chain partnerships. By relocating certain functions to external providers, companies can streamline operations and gain cost reductions. However, this shift can also pose challenges in terms of coordination. Building strong and reliable relationships with outsourcing partners becomes vital to ensure smooth operations and realize the desired outcomes.

- Successful communication channels are fundamental for mitigating potential issues in outsourced supply chains.

- Visibility regarding expectations, performance metrics, and communication protocols is necessary for fostering trust between partners.

Ultimately, the effectiveness of outsourcing on supply chain partnerships relies on a mix of careful planning, strategic communication, and a resolve to fostering mutually profitable relationships.

Vertical Integration in Modern Supply Chains

Coordinate chains have become increasingly complex in the modern era. To streamline efficiency and reduce risks, businesses are exploring vertical integration strategies. This involves controlling various stages of the supply chain, from sourcing raw materials to manufacturing finished goods and even shipping products to consumers.

Implementing vertical integration can bring significant benefits, such as increased influence over production processes, enhanced quality standards, and reduced expenses. By eliminating intermediaries, businesses can expedite the supply chain and enhance their market advantage.

However, vertical integration also presents difficulties. It requires significant capital, skills, and a complex management structure.

Additionally, there are risks associated with dependency on internal operations and the potential for limited flexibility.

Ultimately, the decision to implement vertical integration is a strategic one that depends on a company's unique circumstances, industry dynamics, and long-term aspirations.

Cultivating Innovation through Supply Chain Partnership

Modern businesses are adopting a paradigm shift in supply chain management. The emphasis is no longer solely on cost reduction, but rather on fostering collaboration to drive creative breakthroughs. Co-creation within the supply chain empowers stakeholders, from raw material suppliers to end consumers, to contribute ideas, leading to a more agile and responsive ecosystem. This collaborative approach unlocks new perspectives and fuels the development of innovative products and services that address evolving market demands.

- Furthermore

By breaking down silos and encouraging open communication, co-creation fosters a culture of continuous enhancement. Suppliers gain invaluable market insights, while manufacturers benefit from access to a wider pool of skills. This win-win scenario results in increased efficiency, enhanced product quality, and ultimately, greater consumer happiness.

Strategic Supplier Relationships: Building Value Through Partnership

In today's dynamic business environment, cultivating robust supplier relationships is paramount for achieving sustainable success. Organizations are continuously recognizing the immense value that can be derived from viewing suppliers not merely as vendors, but as valued partners in their supply chain. By nurturing collaborative relationships built on transparency, businesses can unlock a wealth of benefits, including improved efficiency, reduced costs, and increased innovation.

A collaborative supplier relationship framework should be founded on open communication, shared goals, and a commitment to growth. Through frequent engagement and timely problem-solving, organizations can effectively navigate industry challenges and maintain a stable and dependable flow of goods and services.

- Utilizing supplier expertise to foster innovation

- Optimizing supply chain processes for increased efficiency

- Reducing risks through joint efforts

Establishing Trust and Transparency in Supply Chain Networks

In today's globalized marketplace, reliable supply chain networks are indispensable for business success. To achieve this success, it is crucial to foster trust and transparency throughout the entire supply chain. This involves incorporating robust systems for tracking products, guaranteeing ethical sourcing practices, and creating open channels among all stakeholders.

- Moreover, it is crucial to encourage a atmosphere of accountability and visibility within the supply chain. This can be achieved through periodic audits, clear reporting practices, and collaborative initiatives among members.

Effective Supply Chain Risk Mitigation: A Collaborative Strategy

In today's increasingly complex global marketplace, businesses face a myriad of obstacles within their supply chains. These potential issues can range from natural disasters to cybersecurity threats. Effectively mitigating these risks requires a integrated approach that goes beyond traditional, independent methods. A cooperative model emerges as the most effective strategy for navigating these complexities.

By cultivating strong partnerships throughout the supply chain, organizations can exchange valuable information and work together to identify potential threats. This openness enables a more responsive approach to risk management, allowing for rapid mitigation in the browse around these guys face of unforeseen events.

- Strengthening Communication and Collaboration:

- Exploiting Technology for Risk Visibility:

- Developing Resilient Supply Chain Networks:

A collaborative approach to supply chain risk management facilitates a culture of shared responsibility throughout the ecosystem. This coordinated effort not only reduces potential disruptions but also fortifies the overall resilience of the supply chain, ensuring its ability to succeed in an increasingly challenging world.

Multi-tiered Collaborations: Optimizing Supply Chain Structures

In today's dynamic global market, businesses are constantly seeking methods to amplify their supply chain performance. Tiered partnerships, a strategy involving collaboration among multiple players at different levels, presents a compelling approach. By developing a tiered structure, entities can leverage the strengths of each participant, leading to optimized supply chain visibility.

- Advantages of tiered partnerships include:

- Expense mitigation

- Enhanced responsiveness

- Contingency planning

A well-structured tiered partnership can cultivate a cooperative environment where information flows freely, operations are efficient, and worth is enhanced throughout the supply chain.

Supply Chain Transparency in Shared Platforms

Effective supply chain collaboration hinges on the seamless exchange of data. Real-time visibility into inventory levels, consumption patterns, and production capabilities empowers partners to make informed decisions that optimize the entire network. By leveraging data-driven tools, organizations can gain actionable intelligence from shared data, leading to streamlined efficiency, reduced costs, and maximized customer satisfaction.

The Role of Technology in Facilitating Supply Chain Partnerships

Technology drives a vital role in fostering robust and effective supply chain partnerships. By enabling communication, data sharing, and visibility, technology bridges the gaps among partners, promoting collaboration and trust. Cloud-based platforms and software applications offer real-time insights into inventory levels, transportation updates, and demand predictions, empowering partners to make informed decisions collaboratively.

Furthermore, technology optimizes many supply chain processes, such as order processing, procurement, and fulfillment. This frees up valuable time and resources, allowing partners to focus on developing their relationships and coordinating their efforts more effectively.

Ultimately, technology serves as a catalyst for optimization within supply chain partnerships, leading to increased efficiency, cost savings, and enhanced customer satisfaction.

Leveraging Joint Resources for Competitive Advantage

In today's dynamic business landscape, organizations are continuously seeking ways to gain aa distinct edge over their competitors. A key strategy for achieving this goal is leveraging shared resources effectively. By pooling capabilities, companies can optimize their operations, reduce costs, and unlock new opportunities for growth. Collaboration and knowledge sharing foster innovation and allow businesses to address complex challenges more effectively. Furthermore, access to a wider range of resources through partnerships and alliances enables organizations to expand their market reach and serve new customer segments.

Agile Supply Chains: Embracing Collaboration and Flexibility

In today's rapidly evolving marketplace, classic supply chains are struggling to keep pace. Customers demand faster lead times, greater transparency, and customized solutions. To meet these demands, businesses are increasingly turning to agile supply chains, which prioritize collaboration and flexibility. Agile supply chains utilize advanced technologies, such as real-time data analytics and cloud computing, to streamline every stage of the supply chain process. This enables companies to respond quickly to changes in demand, minimize disruptions, and deliver exceptional value to their customers.

- Agile supply chains promote a culture of continuous improvement, with regular feedback loops between suppliers, manufacturers, and distributors.

- Furthermore, agile supply chains are designed to be resilient, able to withstand unforeseen events such as natural disasters or supplier disruptions.

By embracing agility, businesses can gain a competitive advantage in the marketplace and succeed in today's dynamic environment.

Sustainable Practices through Collaborative Supply Chains

Embracing responsible practices within supply chains has become increasingly critical. By fostering cooperation among stakeholders across the entire network, businesses can reduce their environmental impact and create a more transparent system. This collaborative approach allows for the sharing of best practices, alignment of processes, and efficient resource utilization. Consequently, a collaborative supply chain can drive progress in green practices, leading to a more resilient future for all.

Evolving Trends in Supply Chain Partnerships

Supply chains have become increasingly sophisticated, demanding new approaches to partnership. The traditional model of rigid, transactional agreements is being replaced by more collaborative structures. Companies now emphasize long-term synergy with partners across the entire supply chain, focusing on mutual benefits. This transformation is driven by a variety of factors, including increased customer expectations, internationalization of markets, and the need for greater operational excellence. Consequently, we are seeing an increase in partnerships that go further than traditional boundaries. Examples include: Shared visibility of inventory and production schedules Co-creation initiatives Open communication platforms Win-win partnerships This new era of supply chain partnerships promises to realize significant value for all involved parties. However, it also presents obstacles that companies must address successfully.

Building Resilience Through Strategic Alliances

In today's shifting business landscape, resilience is paramount. Companies regularly face unexpected challenges, from economic downturns to disruptive technological advancements. Building a resilient organization requires a multifaceted approach, and one of the most powerful tools at your disposal is creating strategic alliances. By joining forces with other organizations, companies can utilize each other's strengths to mitigate risk, accelerate innovation, and broaden market reach. Strategic alliances allow companies to share valuable knowledge, expertise, and technologies, cultivating a more robust business ecosystem. Furthermore, these collaborations can provide competitive advantages, enabling companies to weather turbulence and emerge better equipped for the future.

The Future of Supply Chain Collaboration: Emerging Models

The realm of supply chain collaboration is undergoing a dynamic transformation, with innovative models revolutionizing how businesses connect across the value chain. Cloud-based platforms are paving the way for enhanced transparency, fostering confidence among stakeholders. Collaborative optimization processes, driven by real-time data and analytics, are enabling responsive solutions to address challenges and optimize efficiency.

- Machine intelligence is augmenting collaboration by streamlining tasks, providing prescriptive analytics, and enabling smart decision-making.

- Additive manufacturing is redefining supply chain designs, allowing for distributed production and reduced reliance on traditional logistics networks.

As these revolutionary trends, the future of supply chain collaboration promises to be a seamless ecosystem where businesses prosper through collective value creation.

Key Performance Factors for Measuring Supply Chain Partnerships

Cultivating robust and effective supply chain partnerships hinges on accurately defining and monitoring key performance indicators (KPIs). These KPIs provide invaluable insights into the strength of the partnership, facilitating both parties to identify areas of strength and areas for improvement. A well-rounded set of KPIs should encompass factors such as lead times, inventory turnover, operational expenditure, and transparency. By regularly evaluating these KPIs, partners can maintain a symbiotic relationship that drives mutual profitability.

Top Strategies for Effective Supply Chain Partnerships

Cultivating robust supply chain collaboration is crucial for businesses striving for maximum performance. Leveraging the collective strengths of your partners through open communication, aligned processes, and mutual goals can unlock considerable value. Establish a culture of trust by consistently involving all stakeholders in the planning process. Automating information flow and integrating technology solutions can further enhance collaboration, leading to enhanced efficiency, lowered costs, and refined customer satisfaction.

- Foster regular interaction between departments and partners.

- Establish clear roles and responsibilities for each party involved.

- Utilize technology platforms to facilitate data sharing and collaboration.

Remember that successful supply chain collaboration is an ongoing process that requires engagement from all participants. By cultivating these relationships, businesses can realize a strategic advantage in today's complex market landscape.

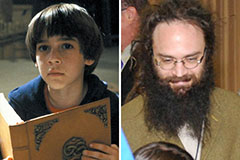

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! David Faustino Then & Now!

David Faustino Then & Now!